ENZO Evaporators

The heat exchanger are at the cutting edge of contemporary refrigeration design and process driven manufacturing

Best ENZO Evaporative Condenser

ENZO EVAPORATORS – The proven performer.

Evaporator are finned heat exchangers serving as components of a refrigeration system, in which liquid refrigerant evaporates with heat absorption from the environment to be cooled. Rishabh Enterprises have partnered with ENZO for commercial refrigeration applications. The powder-coated casing in these Cold Room Evaporators are made of corrosive resistant aluminum alloy and comes with a stainless steel ceiling mounts.

Advantages

- Compact design

- Optimised casing dimensions for transport and storage

- Easy to clean

- Electrical defrost, factory-fitted or as a heating set for installation by customer

Inspection and cleaning

- Easy access to all components

- Heat exchanger can be cleaned from three sides

- Hinged inner and outer trays

- Outer tray is thermally decoupled to prevent water condensation

Key Features

- Heavy duty hinges for longer and safer life

- IP65 Terminal Connector

- Customisable Casing – Al / GI Powder Caoted or SS 304 Casing

Easy mounting

- Hinged side cover for opening

- Hinges allow hang-out

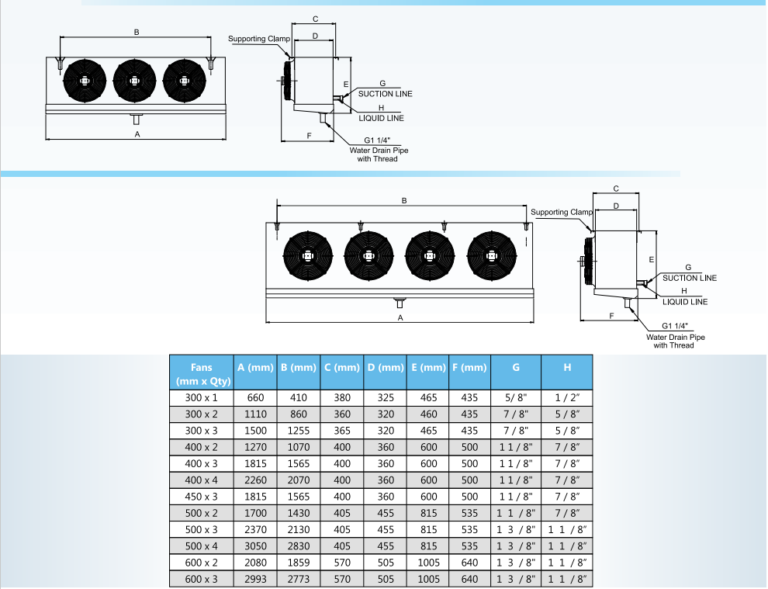

- Ceiling mounting brackets with slotted hole

- Schrader valve at outlet

- Easy access to all components

HACCP hygiene certificate

- All materials used are food-safe

- All components are easy to clean

- Visual inspection of the entire unit possible

- Support bracket flush with upper surface of casing

Suitable Applications

- Commercial refrigeration Industrial refrigeration

- Storage rooms and many types of cAd storage rooms with low and medium humidity

- Room temperatures + 20 to -28 °C

Our Strength: ENZO Evaporators. The heat exchanger are at the cutting edge of contemporary refrigeration design and process driven manufacturing.

The evolution has led to the product development that provides:

Maximum Efficiency through optimized mass flow design. Material & Components specified to World Class Standards. Longer life through appropriate material selection and robust construction.

Heat exchangers: The air coolers are equipped with a staggered tube system, internally grooved tubes and specially pressed fins. Optimised fin systems and adapted pipe circuiting offer safe operation and high efficiency.

Casing

- Corrosion-resistant aluminium alloy AlMg

- Powder coating in RAL 9003

- Stainless steel ceiling mounting bracket

- Options with GI / SS Casing

High-quality tray design

- Corrosion-resistant aluminium alloy AIMg

- Powder coating in RAL 9003

- Hinged inner and outer trays

Top-quality fans

- Standard EC and AC fans available

- ErP-compliant

- Motor protection with thermocontacts

- 50 or 60 Hz

- Customisable with EBM Papst or Zeihl Abbegg

Options / Accessories

- Electric defrost heater for coils and trays

- EC fans

- AC fans

- Heating kit for retrofitting

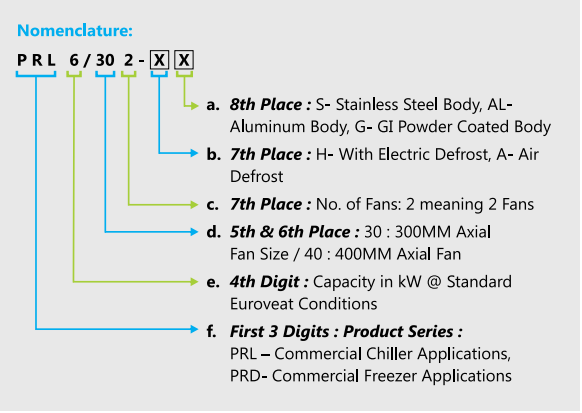

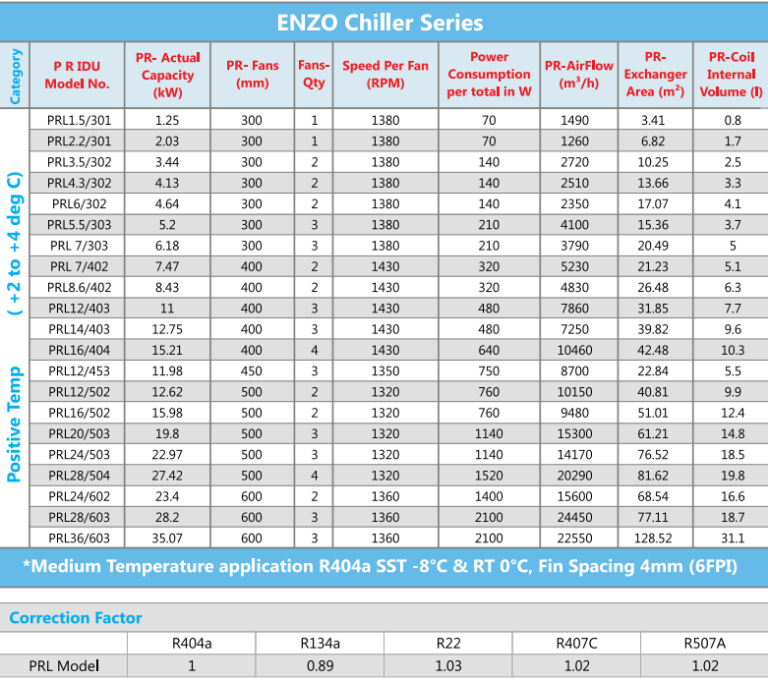

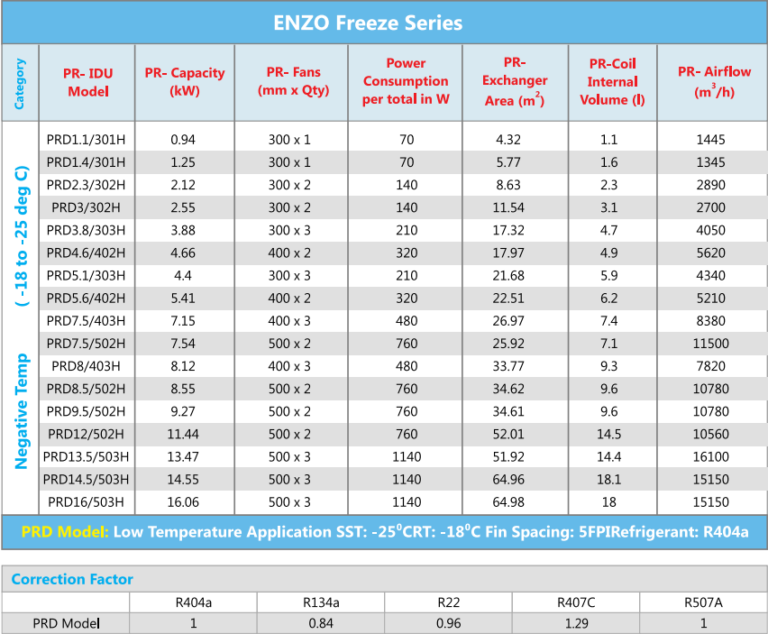

Specifications

a. Copper Tube & Aluminum Fins for different HFC Refrigerants

b. Fin Spacing available from 4FPI to 6

FPI for Chiller & Frozen Applications

c. Casing Options available for SS, GI &

Aluminum Powder Coated

d. BTS ( Built To Suit) Units with different Fan size and type according to application